The architecture of production

Costs do not exist to be calculated. Costs exist to be reduced. - Taiichi Ohno

In the realm of production, complexity is not a bug, it’s often the baseline. Agents operate within layered systems in which constraints, capabilities, and contingencies collide. Yet amidst this chaos, clarity can emerge by first treating production as a black box: a system whose internal intricacies are abstracted to allow a focus on its inputs, outputs, and orchestration methods. This top-level lens allows us to sidestep the noise and engage with the essential dynamics that govern flow, transformation, and value creation. Let’s explore how this abstraction reveals leverage points across upstream provisioning, core execution, and downstream delivery.

The book The Origins of Efficiency describes production as follows:

Outside of the small number of things we can obtain directly from nature, all products of civilization are the result of some sort of production process—some series of transformations that take in raw materials, energy, labor, and information and produce goods and services. At first glance, services might seem far removed from the production of physical goods like cars or shoes, but the same basic model applies. A house cleaner, for example, goes through a specific series of steps—cleaning the bedrooms, then the bathrooms, then the kitchen—using various inputs—labor, electricity, cleaning products—to transform an input—a dirty house—into an output—a clean one.

It is an abstract concept that must achieve fitness from a variety of contexts:

Several factors are at work to make moving production technology from one place to another so difficult. For one thing, there will often be substantial differences between production facilities, even if they’re in the same industry and producing the same goods. Different facilities may have different production volumes, target different markets, or have different product designs. (Aston Martin and Toyota both make cars, but their markets, production volumes, and designs vary dramatically.) They may have chosen other options from the palette of available production technologies, or they may utilize separate standards, such as imperial versus metric units or 120-volt versus 220-volt electricity. They may be operated by organizations with different strategic goals, organizational structures, or work cultures. They may be subject to individual regulatory requirements or have different resources available to them, such as what skills can be found in the local labor pool. In short, a production process, like any technology, doesn’t stand on its own but is always embedded in a particular context—a surrounding environment of resources, knowledge, assumptions, and relationships.

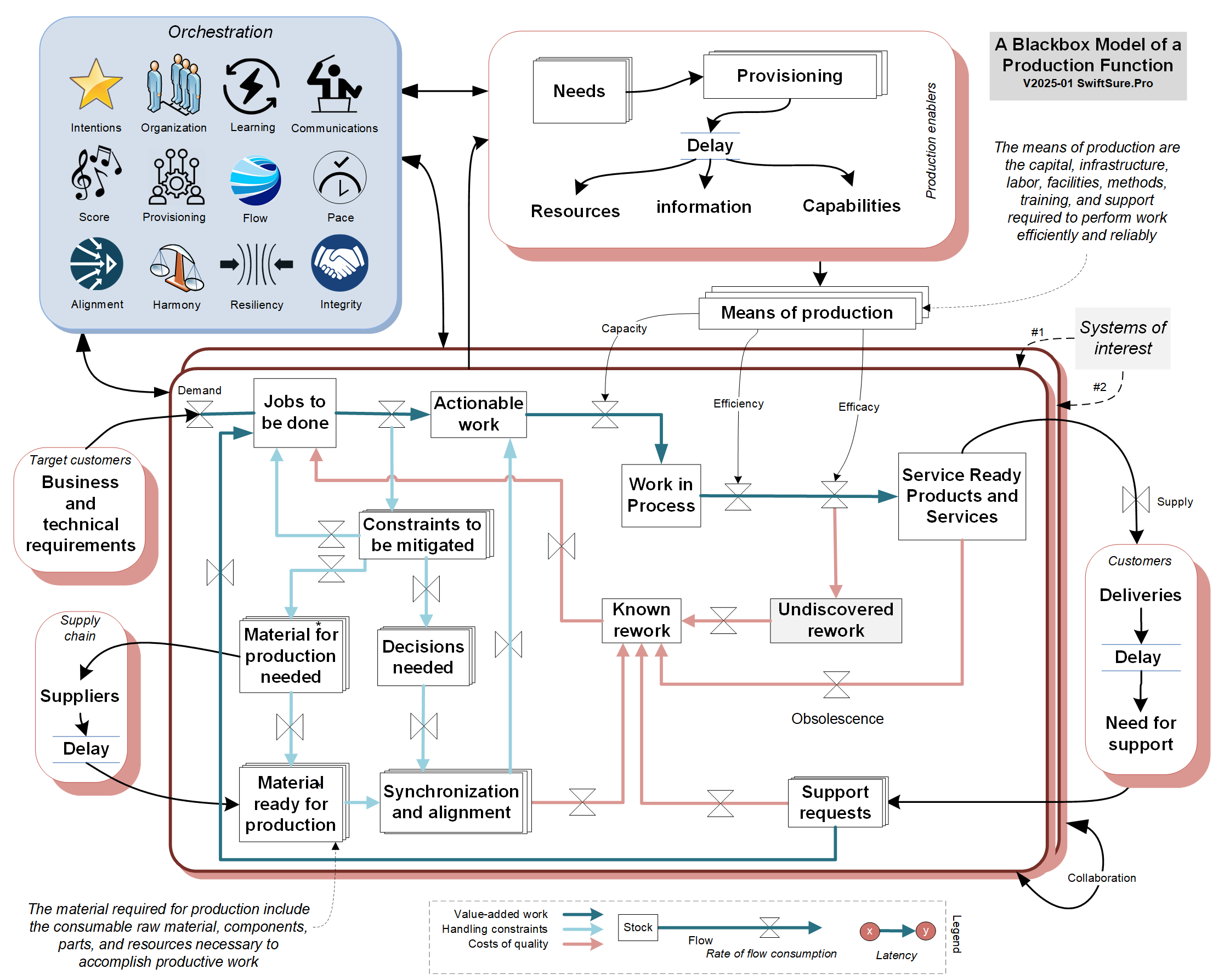

Let’s explore a conceptual presentation of production as a black box, from several perspectives:

the holistic production process that is comprised of lower-level, separate interacting processes of a system of interest

the means of production for that system as separate production systems which provide inputs for the production system of interest

the outputs of the system of interest which serve as inputs to downstream processes (distribution, installation, support, …) and which are also production systems in their own right

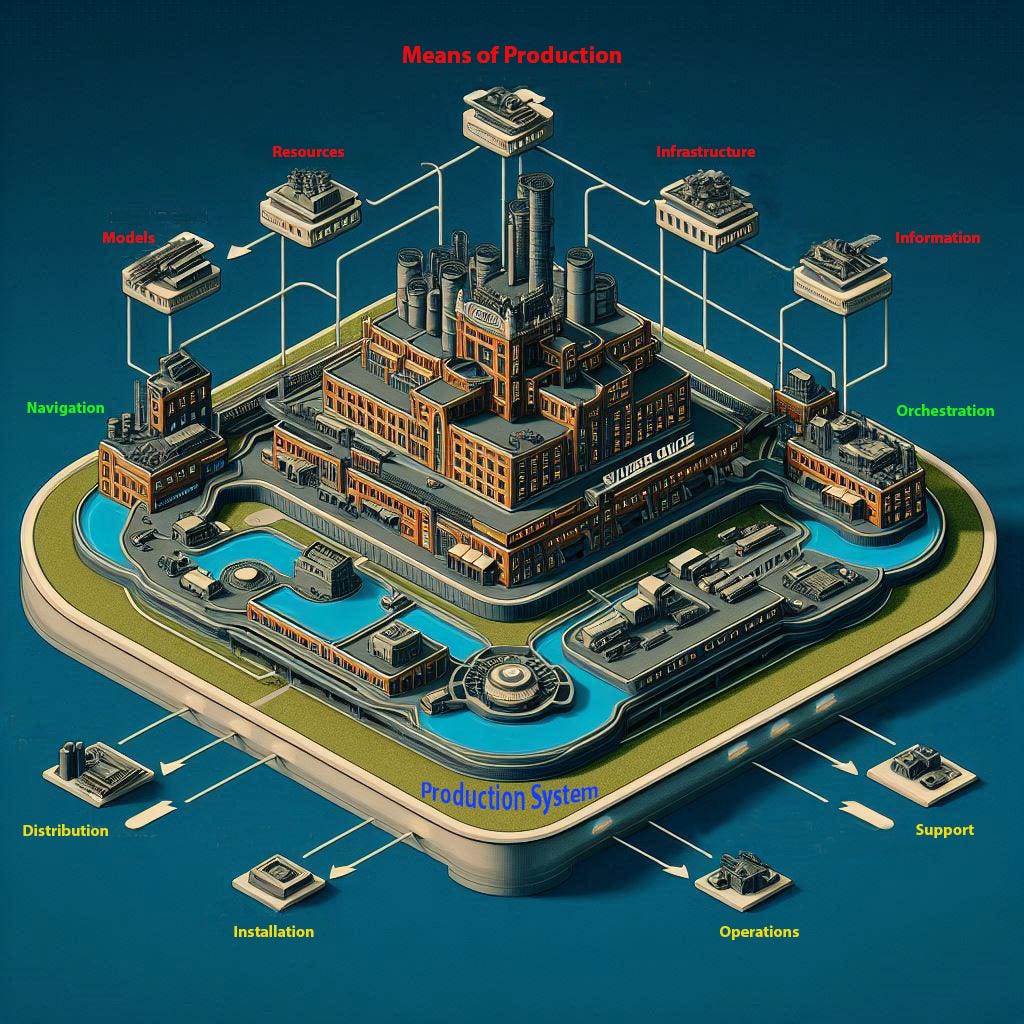

Figure 1 provides a stylistic representation of this structure:

The figure depicts a sprawling, industrial production line reminiscent of Ford’s River Rouge complex. It’s rendered in a gritty, mechanical blueprint style with heavy textures and large machinery evoking the grand scale of an early 20th-century factory. This depiction reinforces the recursive and reentrant aspects of any production system of interest:

Primary System of interest: At the heart of the image sits a large, complex machine labeled “Production System” and acts as the central node for a network of capabilities. It is robust and intricate, with branches and interfaces suggesting dynamic interactivity.

Upstream Systems: Across the top of the primary system of interest, there are several interconnected feeder lines, each themselves production systems. These stations are labeled respectively as Resources, Models, Infrastructure, and Information, and are connected to the system of interest by transportation elements that supply necessary inputs. depicting the flow of elements necessary to drive and fuel the system. The supply of the primary system of interest depends upon the adequacy of supply from these upstream systems. These collectively are often described as the Means of Production, and correspond to Elon Musk’s conceptualization of a factory as a machine:

The true difficulty, and where the greatest potential is, is building the machine that makes the machine. In other words, it’s building the factory. I’m really thinking of the factory like a product.

Downstream Systems: Extending from the system of interest across the bottom of the figure, the primary system of interest interfaces with other production systems - Distribution, Installation, Training, Operations, and Support - that are instrumental in delivering value to customers. These downstream systems are shown as extension bays where the finished output is processed, refined, and prepared for usage in service.

Coupling: Bright lines symbolize the active, continued flow of energy, information, and materials across these elements.

For examples of this hierarchy, consider the architecture of living systems.

Production functions

In economics, the utilized amounts of production inputs determine the quantity of output through a relationship called the production function. It is a key concept in mainstream neoclassical theories, where it is used to consider marginal products and to evaluate allocative efficiency. These uses involve applying the input factors of production and observing their resulting effects on output, while abstracting them from the technological problems of efficiency as an engineer might understand it. These concepts consider production as a black box with a ‘happy path’ mindset.

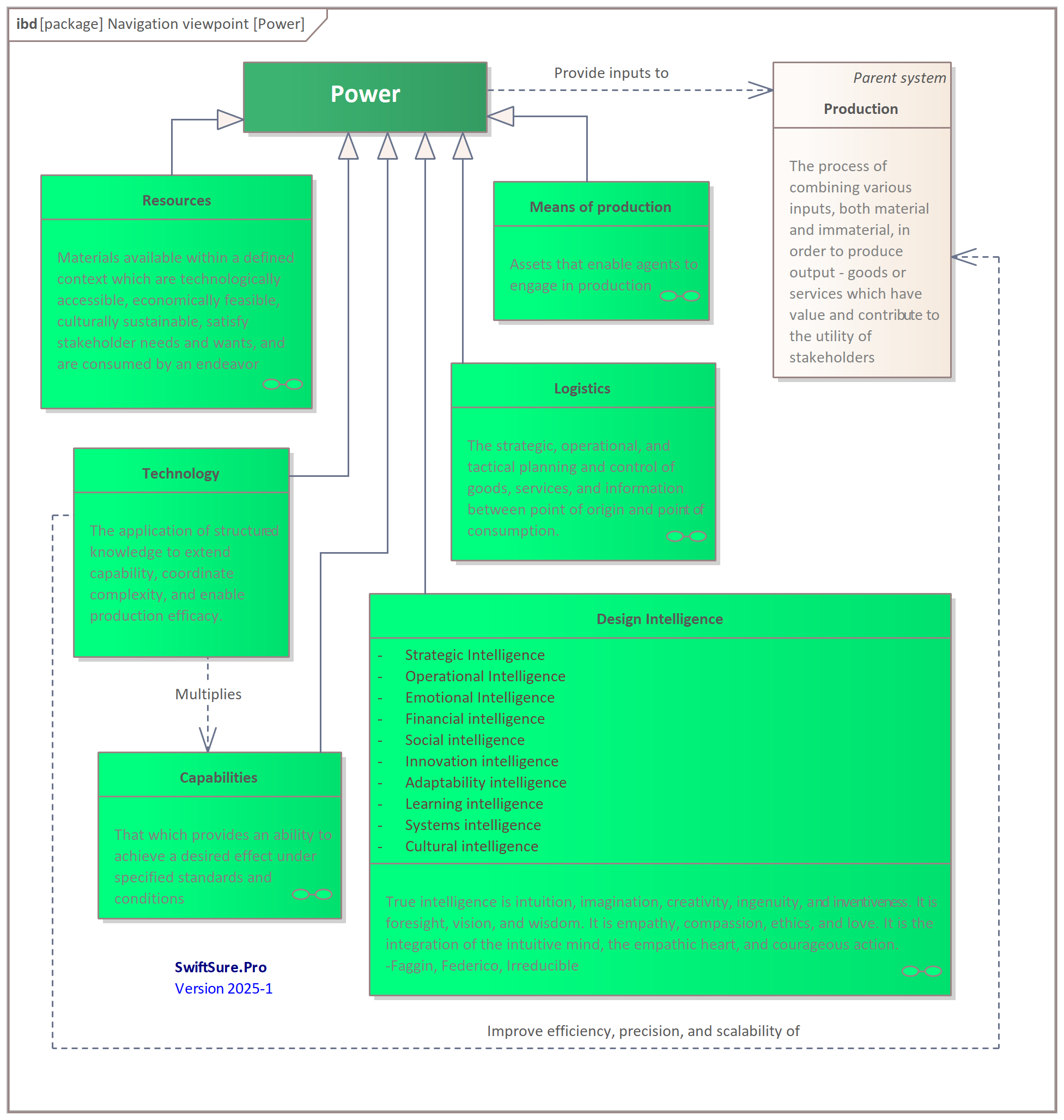

Powering the means of production

In a production process, factors of production, resources, or inputs are used to produce outputs, i.e. goods and services. There are four basic resources or factors of production: land, labor, capital, and the capability to apply these efficiently. Materials and energy are considered secondary factors in classical economics because they are derived from land, labor, and capital. These primary factors facilitate production but neither become part of the product (as with raw materials) nor become significantly transformed by the production process (as with fuel used to power machinery). In my rendering, I use a different term - power - to delineate differences from classical economics and connect to engineering concepts. In the context of production, power looks like this:

Production and capabilities

Capabilities are like means of production but supplement them by providing expertise for agents to implement the transformations of production efficiently and effectively.

These capabilities become the ‘levers’ by which production optimization can be performed.

Conduction, current, and transducers

In physics and electrical engineering, a conductor is a type of material that enables the flow of current in one or more directions. A flow of negatively charged electrons transfers this current from the current source to those consuming it (the loads). Each charged particle nudges its neighbor a finite amount, causing a chain reaction that powers the consumer loads. Many factors influence these transfers - including the material’s properties, cross-section, length, temperature, and ampacity. They also determine its resistivity, or ability to oppose the current, which leads to energy dissipation.

Production and conduction share similar roots. Each term carries a nuance of guiding, channeling, or bringing forth something new. Production’s Latin roots - pro- (“forth”) + ducere (“to lead”) - imply bringing something into being through agency and transformation. Its semantic twin, conduction, has similar roots: con - (“with, together”) - and injects the idea of collaboratively working together to channel or transmit the outputs of producers to the inputs of consumers. This systemic flow exploits the structure, medium, and policy of production to enhance behavior. Transducers are used to code outbound messages from producers into the ‘language’ of the downstream consumer, and to decode messages received from upstream producers into the equivalent for internal processing.

The medium of conduction brings another idea into play. The payload being transmitted is subject to noise, and is also often amplified, filtered, lost, or itself transformed as it is exchanged. These characteristics play heavily in the effectiveness of connections across elements, and how they perform as a unified whole. They also connect each production system with its means of production; when the channel capacity of these connections is not adequate for demand, delays are injected into processing. The reason may be conduction sludge.

Characterizing flow over time

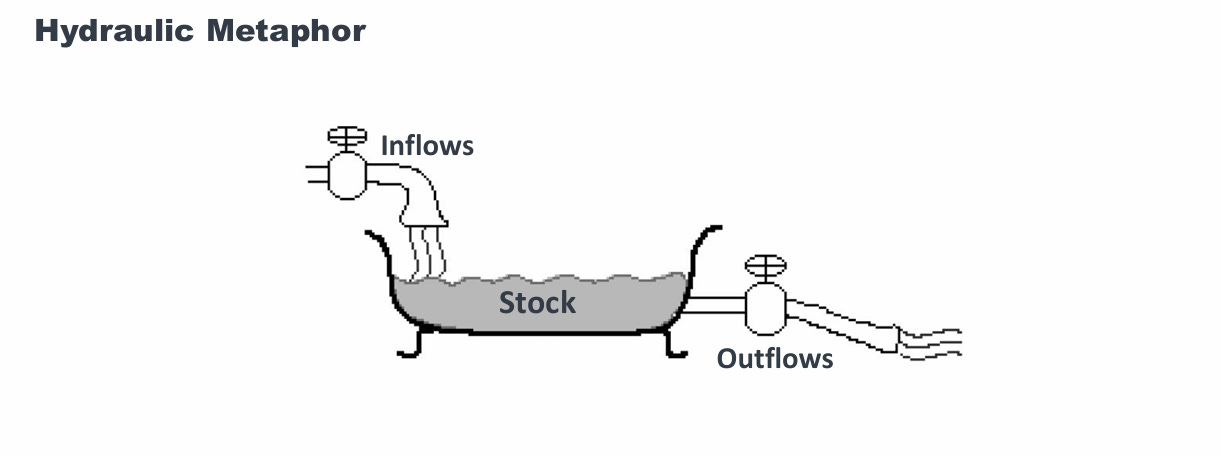

Economics, manufacturing, and accounting fields often distinguish between quantities that are called stocks and those that are flows. These differ in their units of measurement. A stock is measured at a specific point in time and represents a quantity existing at that time, but which may have accumulated from prior flow. A flow is a ‘valve’ which defines the quantity passed through a particular point within an interval and is thus measured in quantity per units of time, analogous to rate or speed.

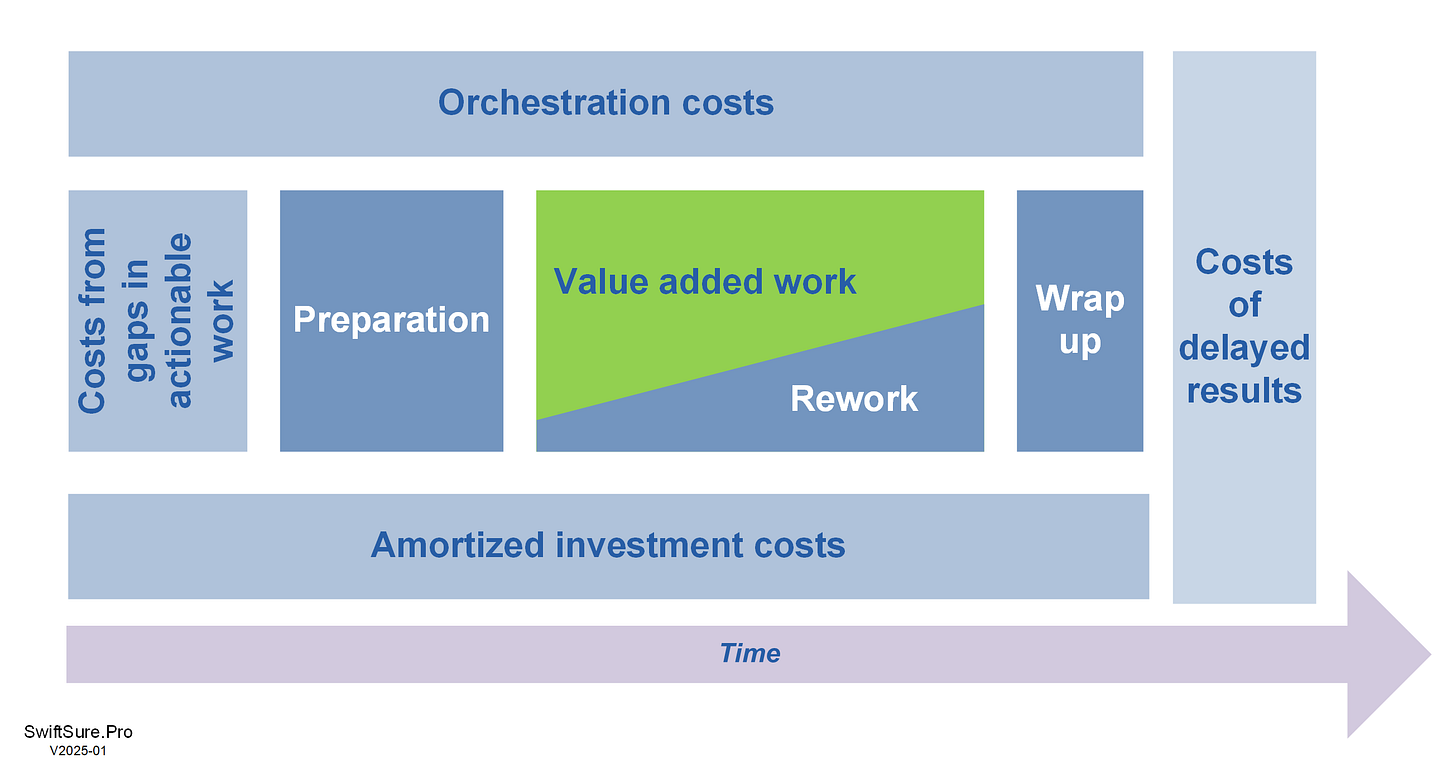

Flow concepts are important to gain operational insights on performing work once authorized, as shown in Figure 3:

This structure represents the aspects of operational costs from a lifecycle viewpoint and highlights the impacts on these costs from delays and quality escapes. To thrive within this structure, the drivers of cost from each element in Figure 3 must be actively orchestrated. This requires understanding the rate at which various kinds of work can be performed, how that evolves with time, and the longer-term consequences of short-term thinking. Planning, designing, and managing these rates are critical skills to facilitate learning and optimization. Let’s explore some examples in which stocks and flows are critical factors for production in economics.

Flows are used to represent income, spending, saving, fixed investment, inventory investment, and labor utilization. Capital is a stock concept which can be invested to produce a periodic income which is a flow concept. A person or country might have stocks of money, assets, liabilities, wealth, means of production, and inventories. It can be invested in human capital (or labor power). A simple view of these concepts is provided in Figure 4.

The gross domestic product refers to the total number of dollars spent within a period. Therefore, it is a flow variable with units of dollars/year. In contrast, the U.S. nominal capital stock is the total value, in dollars, of equipment, buildings, and other real productive assets in the U.S. economy, and has units of dollars.

A black box flow model

These concepts are also particularly helpful in thinking through a development process flow. Figure 5 shows how work is processed through a typical value chain. In this figure, there are two systems of interest depicted, one behind the other. They must collaborate to deliver service-ready products and services. As Figure 1 indicated, there are many production functions that require orchestration, but they all share the same conceptual structure:

Let’s break down these components and their responsibilities:

Orchestration (top left)

Sets direction, pace, and structure

Feeds Needs and balances supply of what must be provisioned across the production systems of interest

Production enablers (upper right)

Translates needs of system of interest into actual Means of Production (resources, infrastructure, capabilities)

Includes a provisioning delay, depicting the real-world lead time to hire/train, procure hardware, and deploy processes

Execution & Flow (center)

Jobs to be Done → Actionable Work → Work in Process → Service-Ready Products & Services

Stocks (rectangles) accumulate WIP, service-ready inventory, raw materials.

Flows (valves) show conversion rates, capacity constraints, and rework loops.

Constraints to be mitigated fall into two classes: material needs and decisions needed. The rate at which these constraints can be mitigated determines the delays in flow from their discovery.

Demand & Delivery (left and right edges)

Target Customers define business/technical requirements.

Customers receive deliveries and generate support requests (which brings another delay).

Key Dynamics & Feedback

Capacity ↔ Demand Balancing

Capacity (a dynamic property of the Means of Production) must scale to match the demand, or the rate work enters the system

Undershooting demand with capacity creates queues which delay delivery, while overshooting it ties up investment in idle capacity

Rework Loops

Known Rework and Undiscovered Rework both send items back from WIP or even service-ready stock into earlier stages, incurring additional costs of quality.

Support requests → Jobs may delay responsiveness to customer needs unless provisions for expedited service are provided.

Decision Points

Trigger where and when to invest (scale infrastructure, hiring, …) or mitigate constraints (bottlenecks, material shortages).

Provide opportunities for adjusting allocational efficiencies.

Delays & Latencies

Provisioning, supplier lead times, and support-response delays all introduce oscillations if not smoothed by buffers or governing policies.

Conduction issues can inject undesirable effects into transfers.

By modeling production as a black box, we gain a powerful vantage point for diagnosing inefficiencies, identify opportunities to learn to enhance throughput, and align capacity with demand. This black-box abstraction doesn’t ignore complexity, it channels it. Whether we’re scaling infrastructure, mitigating rework, or navigating provisioning delays, this viewpoint helps us see the system as a whole and think through strategies to act with precision. In a world where costs are not merely calculated but must be reduced, this orientation offers both strategic clarity and operational leverage.

The next step in this series involves understanding how to optimize such situations is to dive into a post about how production breaks down.