Throughput workflows and priorities

Treating symptoms may offer temporary relief, but unless you uncover and address the root issue, the problem will resurface—often more complex than before.

In the quiet chaos of production, where customer expectations outpace delivery pipelines, workflow design becomes not just a matter of efficiency, but survival. Beneath the surface of neatly diagrammed project plans lurks a deeper challenge: how to manage the flow of work when complexity, variability, and human limitations collide. How can better prioritization, systemic insight, and a shift in mindset transform bottlenecks into breakthroughs?

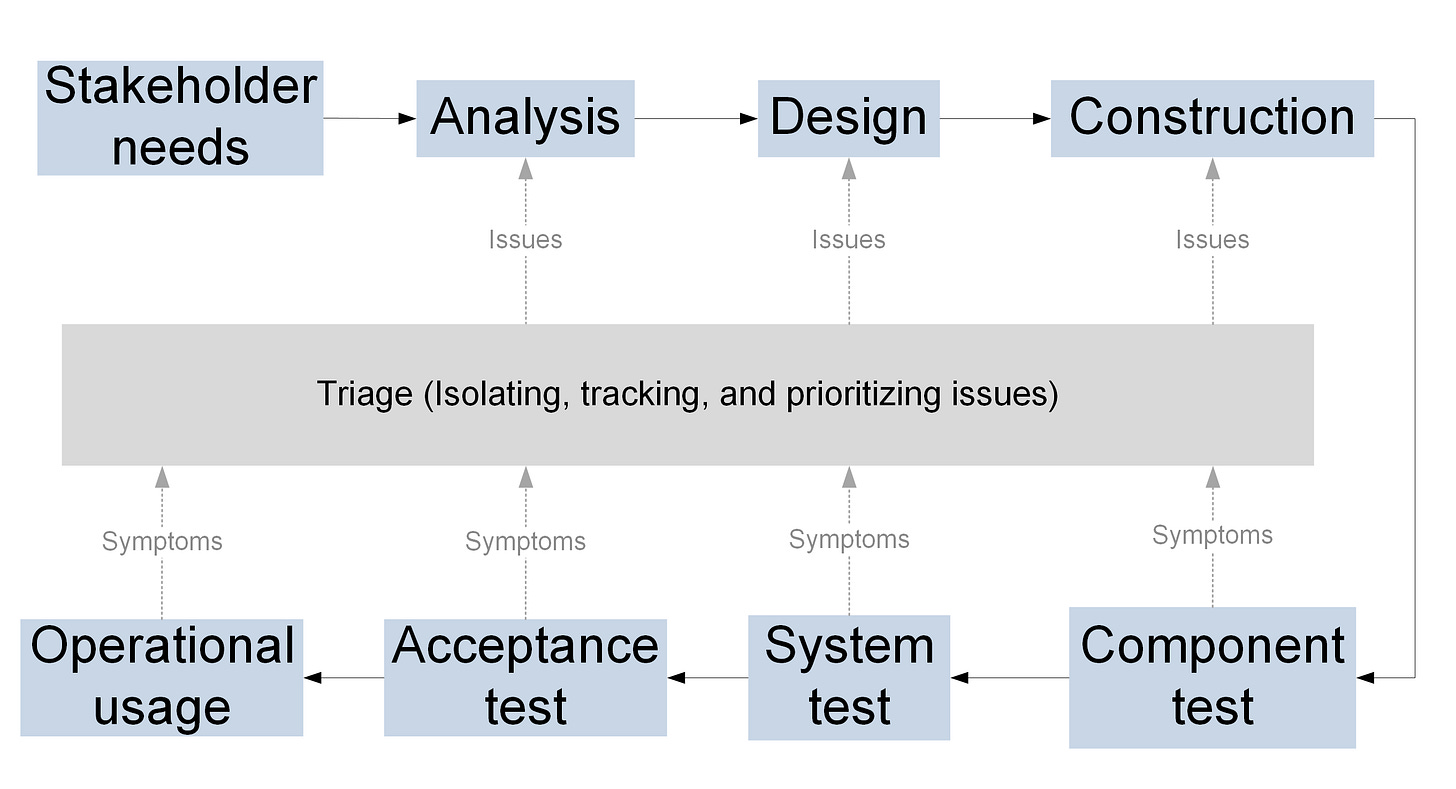

A workflow is a repeatable pattern of activities that systematically organizes actors to transform information, materials, and energy into products. The Rational Unified Process illustrates this well by breaking down work into sequential phases, each requiring time and effort to create intermediate work products necessary for shippable features.

But in practice, inputs often arrive according to business cycles, not customer demand. When the volume of incoming work outpaces the processing capacity of each workcell, bottlenecks form. Delays snowball, requiring more resources and rework downstream. These growing queues aren’t just nuisances—they signal a systemic imbalance between demand and throughput.

The Cost of Congestion

As queues expand, performance deteriorates. Teams divert resources reactively, which masks underlying inefficiencies rather than resolving them. Like rush-hour traffic, even a small dip in capacity can cascade into major slowdowns. The temptation to push incomplete work forward creates defects that emerge later—when they’re far more expensive to fix.

Why Prioritization Matters

Prioritizing before work enters the system may face resistance, but once customers experience shorter cycles and more predictable delivery, the value becomes clear. Smart prioritization isn’t about picking favorites - it’s about stabilizing flow so high-value work moves smoothly from start to finish.

Designing for Context

Unique products call for different development models. As Michael Cusumano notes, high-end custom systems require deep user engagement and expert tools, while mid-range offerings benefit from standardized processes that balance cost and customization. Mass-market products, by contrast, thrive on maximizing value for the average user.

Seeing the Invisible

Manufacturing benefits from visual cues - inventory piles up where flow breaks down. Engineering lacks that visibility. Without tangible artifacts, inefficiencies go undetected, leading to unreliable throughput estimates. And traditional project plans often assume idealized, linear progress that’s rarely achieved.

Variation arises from two sources: assignable causes (clear execution failures) and random noise (systemic complexity). The former calls for better quality control; the latter demands systemic change.

Shaping Smarter Teams

Multi-skilled teams can adapt on the fly to balance queues and maintain cadence. Visual indicators - distinguishing customer-driven work from internal refactoring - support better decision-making. Over time, as teams learn their true pace and capabilities, they can make credible commitments to stakeholders.

But that only works if work enters the system in a ready state, with strict limits on in-progress inventory. Planning must begin with ideal assumptions - perfect timing, full capacity, zero defects - that are then adjusted for reality, making risks visible and prioritized accordingly.